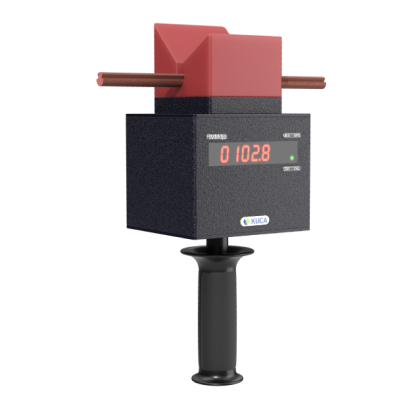

The meter is offered in two versions:

RMMdjp – for measurements following overhead contact line shutdown. Measurements are taken by means of a maintenance vehicle.

ZMMdjp –for measurements with a overhead contact line in operation. Measurements are taken without a maintenance vehicle.

The most important features and advantages:

RMMdjp Set:

ZMMdjp Set:

If you have any questions please contact our Sales Department

We have the ability to produce standard metric threads:

M10, M14, M16, M18, M20, M22, M30, M48 of any length

and fine-grained:

M10x1.25, M12x1.25, M12x1.5, M14x1.25, M14x1.5, M16x1.5, M18x1.5, M18x2, M20x1.5, M20x2, M22x1.5, M22x2 of any length

We have a HK-40 two-roller rolling mill with a pressing force of up to 40 tons and a maximum stroke of 7 mm

Please send inquiries to the following address: j.bluj@kucagroup.pl

In KUCA company, we have unique experience in forging copper alloys. Our copper forgings feature good electrical conductivity, ductility, machinability and wear resistance. These products are able to withstand high temperatures and greater load than other materials.

Staff specialized in the field of die forging deals with the design of forgings in accordance with the needs of customers as well as design and production of matrices and development of the technological process.

The forging process in our company is fully automated. We have 150 kW induction heaters for copper alloys and a screw press with an impact force of 640 tons, which work closely together. In addition, we have an annealing furnace and shotblasting machines for cleaning forgings from scale.

KUCA Sp. z o.o. is a certified producer of steel structures.

In its activity, it meets the requirements of the PN-EN 1090-2: 2018 standards, the EN ISO 3834-2 welding standard and the EN 15085 standard.

In accordance with EN 1090-2, we produce elements of load-bearing structures and their sets made of steel up to the EXC3 class.

Rail vehicles and their components in accordance with EN 15085-2 are manufactured up to the CL1 level.

Large constructions are produced in a production hall equipped with two overhead cranes with a lifting capacity of 8T. The cranes work at the length of 60 meters and width of 14 meters. Additionally, we have a turntable with a lifting capacity of 6.3T.

Large production series of small elements can be made using a six-axis welding robot equipped with a stationary and rotary table.

Basic data:

A stationary table with dimensions of 1200×2800

Rotary table with dimensions of 1200×2960 and load capacity up to 500 kg.

The maximum range of the robot arm R = 1904mm

MIG / MAG welding with an intensity of up to 340A in a 100% cycle and 440A in a 60% cycle.

COOPERATION OFFER OF KUCA Sp. z.o.o. FOR METAL

INDUSTRY COMPANIES IN THE FACTORY EMPLOYING

INMATES IN STARGARD PENITENTIARY

On April 27, 2016, a program on the work of prisoners was announced by the Ministry of Justice and the Central Board of Prison Service. KUCA Sp.z.o.o. was selected as a partner for the cooperation of the Government Work Program for Prisoner Workers: “Employment of convicts” by building a production facility KUCA Sp. z.o.o. within the premises of the prison services in Stargard and start production in the newly built facility.

According to the assumption of the program, the newly created halls employ mainly inmates serving sentences in closed-type prisons, i.e. the category of inmates in which, due to the conditions of serving a sentence, the percentage of employment of inmates is the lowest. The funds for the construction of the halls come from the Fund for the Vocational Activation of the Convicts and the Development of the Prison Based Production Facilities.

COOPERATION PROPOSAL FOR PARTNERS REPRESENTING THE FOLLOWING INDUSTRIES: METAL, RAILWAY, AUTOMOTIVE, ENERGETIC (outwork for inmates)

If you are interested in our offer please contact manager Rafał Czajka, tel. +48 512 037 528

KUCA Serwis Kolejowy Sp. z o. o. has experienced and well-qualified staff as well as specialist two-way machines, therefore, it offers comprehensive execution of construction works in the scope of:

KUCA Serwis Kolejowy Sp. z o. o. has experienced and well-qualified staff as well as specialist two-way machines, therefore, it offers comprehensive execution of construction works in the scope of:

KUCA Serwis Kolejowy Sp. z o. o. has experienced and well-qualified staff as well as specialist two-way machines, therefore, it offers comprehensive construction works in the field of renovation, construction and modernization of non-traction power networks and devices, including:

Renovation and repair of semi-trailers

As part of renovation and repair works, we offer:

Offer downoload

A two-way platform with a load capacity of 20 tons

The platform is used for track works. After entering the platform, vehicles like excavators and loaders can perform track work from its level. Due to this solution purchase of expensive two-way machines is unnecessary.

After its production the platform can move on a closed railway tracks. Additionally, Kuca Sp. z.o.o. can equip the platform, at client’s request, with anti-bike covers with type-approval, lighting, bumpers and other required elements in order to obtain road type-approval in accordance with GDDKiA.

The most important technical data:

If you have any questions please contact our Sales Department